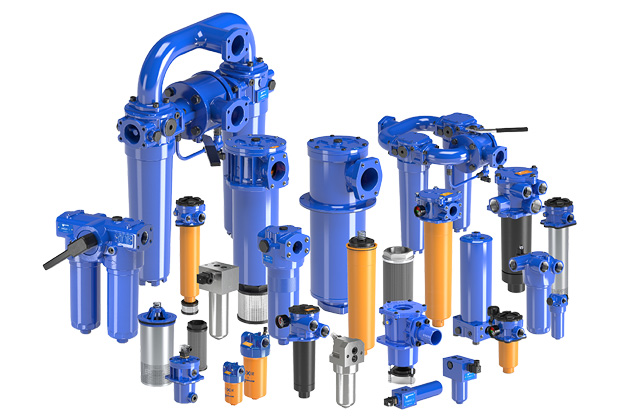

Highly-efficient filtration systems depend on the correct design of hydraulic machines and their hydraulic systems. These have become increasingly complex with the development of high-quality components, designed and manufactured for high-performance. Designing a filtration system means evaluating the type and location of the filters in a specific hydraulic system in relation to: sensitivity of the individual components, degree and type of contamination, circuit pressure/flow rate, environmental conditions, fluid used and intervention cycles, guarantee of a longer life of the machines than expected.

The MP Filtri “N” series “A” type inorganic glass fibre media Beta 1000 elements have been tested in accordance to the ISO16889 standard, for technical details please see filter series technical data file. Please also refer to the filter element technology information within the Knowledge Centre.

SUCTION FILTERS AND STRAINERS

SUCTION FILTERS AND STRAINERS

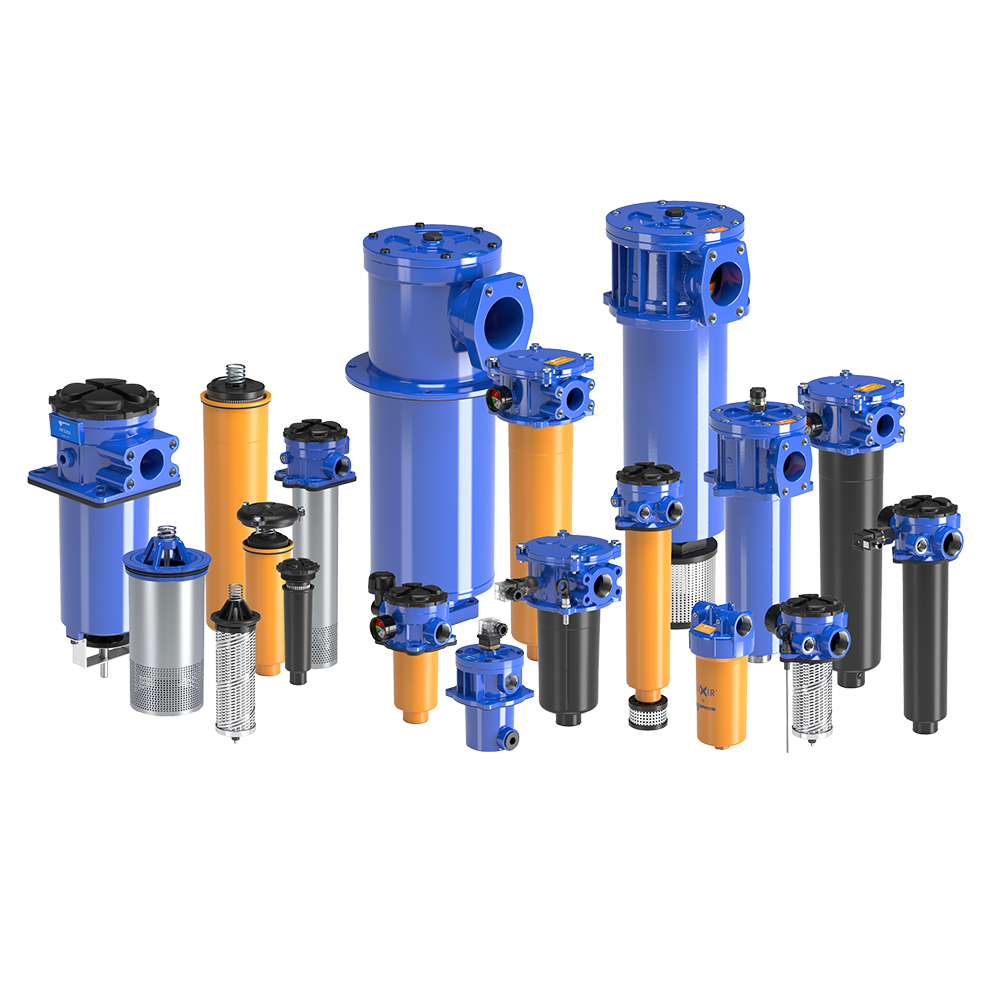

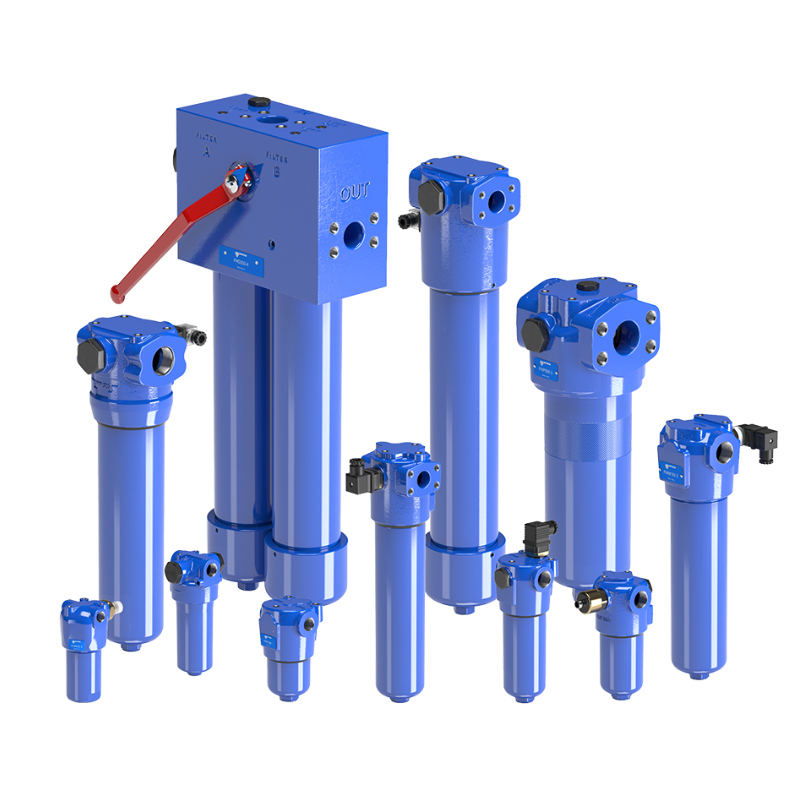

RETURN FILTERS

RETURN FILTERS

RETURN/SUCTION FILTERS

RETURN/SUCTION FILTERS

SPIN-ON FILTERS

SPIN-ON FILTERS

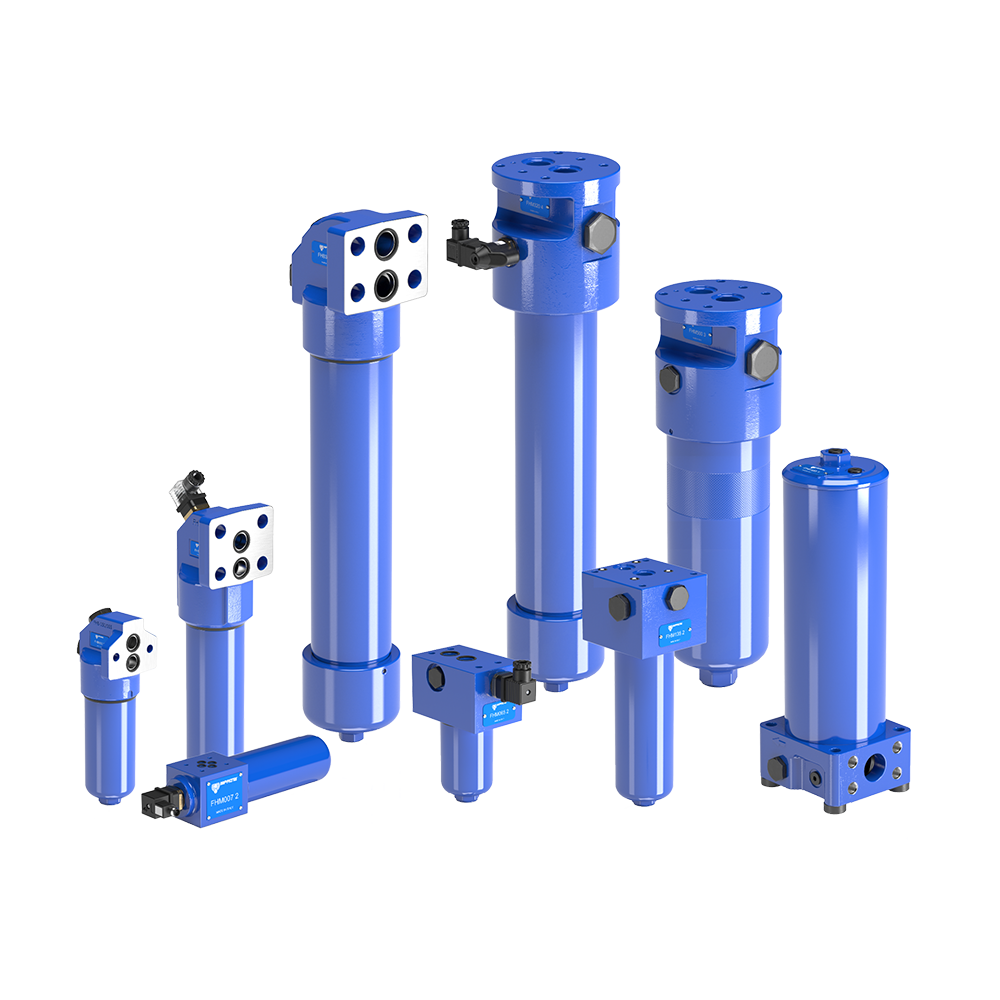

IN-LINE FILTERS, <= 80 BAR (LOW & MEDIUM PRESSURE)

IN-LINE FILTERS, <= 80 BAR (LOW & MEDIUM PRESSURE)

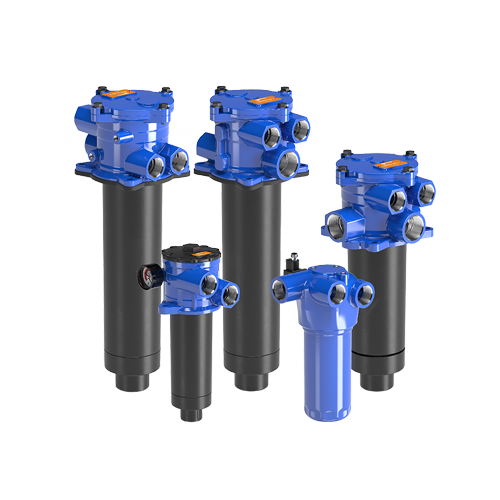

IN-LINE FILTERS, > 80 BAR (HIGH PRESSURE)

IN-LINE FILTERS, > 80 BAR (HIGH PRESSURE)

MANIFOLD FILTERS, > 80 BAR (HIGH PRESSURE)

MANIFOLD FILTERS, > 80 BAR (HIGH PRESSURE)

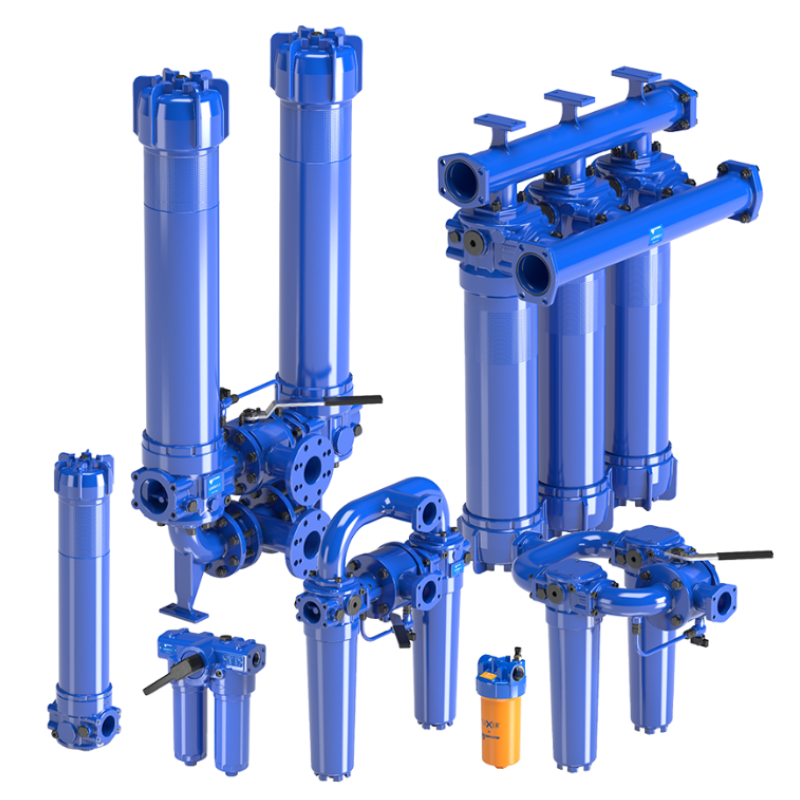

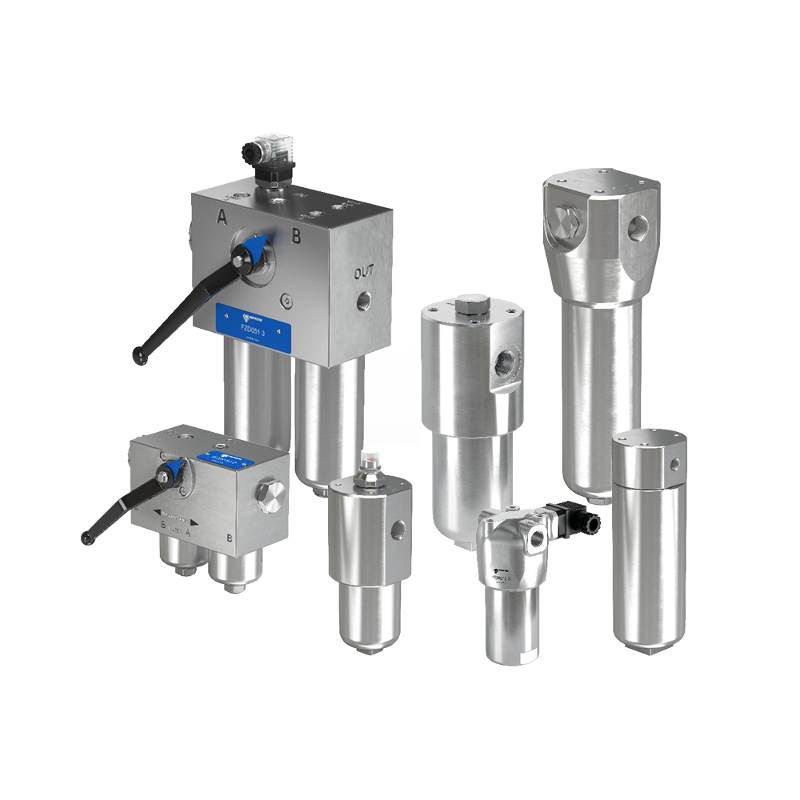

IN-LINE STAINLESS STEEL FILTERS, <= 1000 BAR

IN-LINE STAINLESS STEEL FILTERS, <= 1000 BAR

MANIFOLD STAINLESS STEEL FILTERS, <= 320 BAR

MANIFOLD STAINLESS STEEL FILTERS, <= 320 BAR

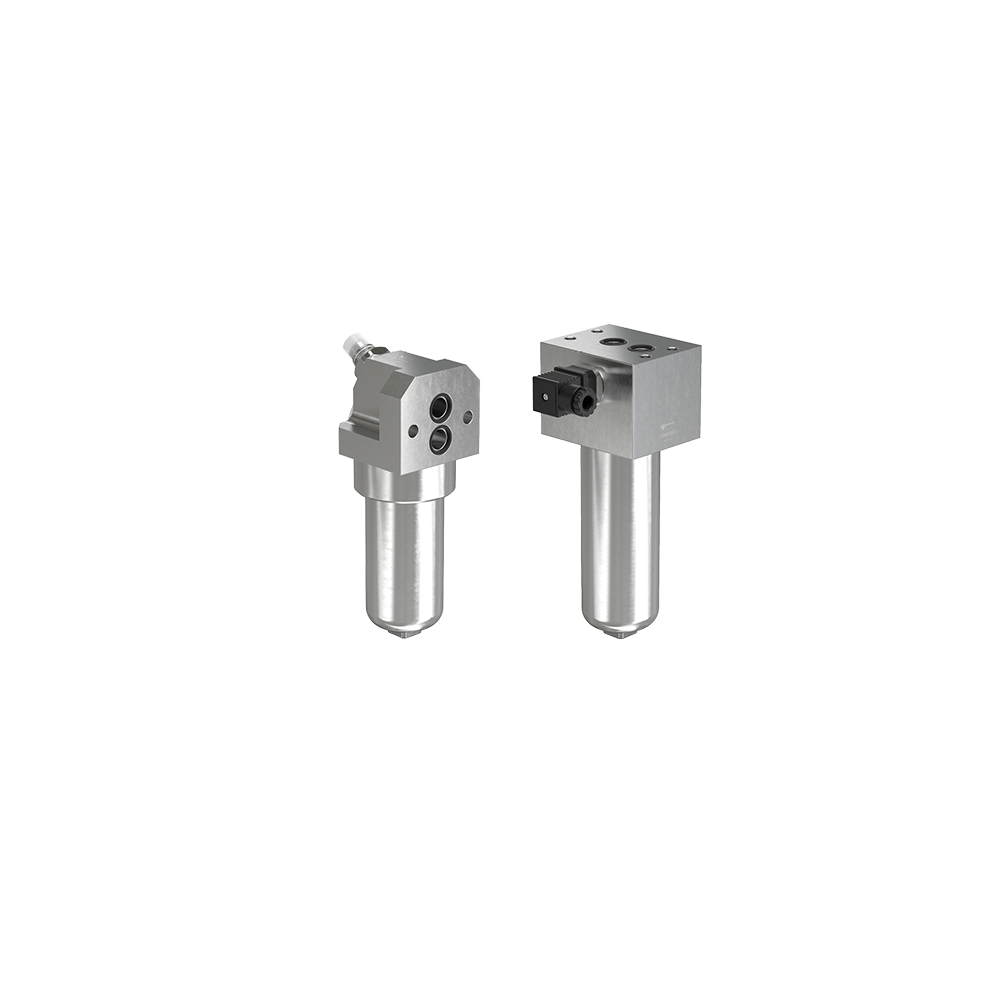

FILTERS FOR POTENTIALLY EXPLOSIVE ATMOSPHERES (ATEX)

FILTERS FOR POTENTIALLY EXPLOSIVE ATMOSPHERES (ATEX)

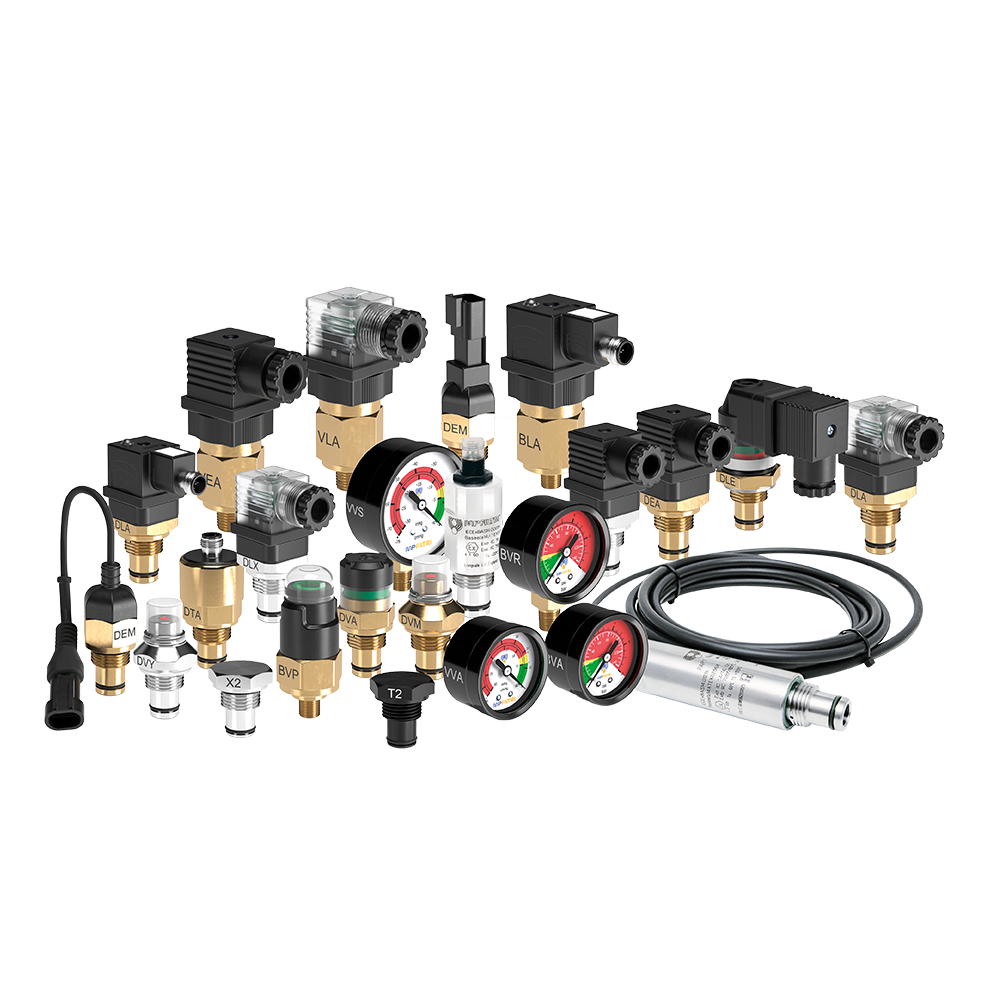

CLOGGING INDICATORS

CLOGGING INDICATORS